|

We are different than most Geothermal design companies, we do not own an installation company. We provide you the best economical energy saving solution. With our proven design plans and knowledge you can move forward to do it yourself, all or in part, and/or contact several geothermal installers, this approach allows you to get the best price. We do have a list of geothermal installers you can call if you wish. |

|

For a free consultation to see what type of geothermal system best fits your needs please contact us. |

|

The ground loop is a key part of the geothermal system and it must be properly designed and installed. The plans to the loop field are easy to understand but applying the technology to the design is quite complicated. Careful design is necessary to ensure that there is sufficient capacity available for the geothermal heat pump to operate properly. Design consideration is crucial when spacing the pipes in a loop and is important as this affects how much the heating or cooling effect of one pipe influences the heat source or heat sink available to adjacent pipes. |

|

One main consideration in any geothermal design is the geographic region. One size or design does NOT FIT ALL. While the ground loops are basically the same, careful consideration is addressed for the prolonged seasonal changes, which you will be most needed, heating or cooling. |

|

Geothermal Loops |

|

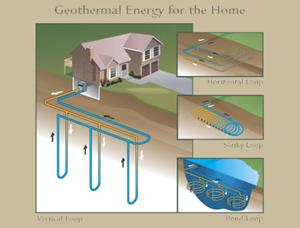

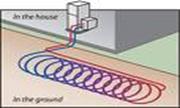

We review all natural resources available. Geothermal does not mean just pipes in the ground. There are options such as Hybrid Geothermal. These designs include a lake or pond on or accessible to the property. There are open and closed loops. In some regions include a swimming pool and incorporating an evaporative fluid cooling tower. |

|

Several types of loops are considered when designing your system. No matter what loop configuration is used all loops are tested under pressure prior to their being buried in the ground. One main consideration in any design is the geographic region. As stated before, one size or design does NOT FIT ALL. |

|

While the ground loops are basically the same, careful consideration is addressed for the prolonged seasonal changes, which will be most needed heating or cooling. |

|

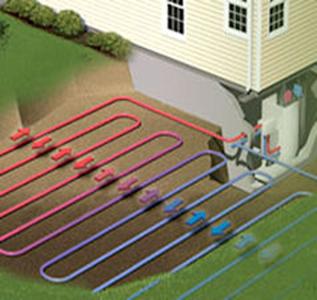

The different types are as stated, open or closed. A open loop will pull water from its resources then utilize it transferring the energy then discharging it back out to its designed or designated place. This is normally from ponds or vertical ground well systems. A closed system is utilizing the same fluid enclosed in a pipe or tube system. Once used it is discharged to the loop system where the energy is transferred and then recycled to be used again. In most cases within this loop contains a special mixture of water and an antifreeze solution. |

|

Open & Closed Loops |

|

Vertical loops are the most common and require the least ground area for installation with little disturbance to the ground surface. For residential systems, holes are most commonly drilled to a depth of 150-200 ft and are spaced a minimum of 10 ft apart. In most regions, as a rule, one hole is required for each ton (12,000BThU/h) of heating or cooling depending somewhat on the subsurface material. Most installers usually use a water well rig to drill the holes therefore access to the drilling area for a truck is necessary. When the pipe has been inserted the hole a heat conductive grout is being applied. This serves several purposes, ensures good heat communication between the pipe and the ground, and also seals the hole so that there can be no groundwater contamination or flow within the hole. From each vertical loop a trench is dug between the holes and one leading to the house to a depth of about 3 ft. The pipes are connected together by using a manifold pipe. |

|

Vertical Loops |

|

There are several designs utilizing different installation techniques. One approach for a horizontal loop is buried in trenches at a depth of 6-8 feet or in a larger pit at a depth of about 10 ft. Trenches can be anywhere up to 150ft long depending on the pipe configuration. The geothermal pipe can be laid in a trench in long straight lengths on each side of the trench, and sometimes at 2 levels in each trench. This requires trenches at least 3 ft wide. Another approach is becoming popular, a slinky configuration is used and the pipe is laid in a trench about 5 ft wide in a semi-coiled manner. Each trench often provides 1 ton of heating or cooling although this depends very much on the pipe configuration and the type of ground. The horizontal design requires a sizable area of land depending on the required of heating or cooling needed. For new construction, there can be some cost savings compared to a vertical loop particularly if digging machines are already available at the site. |

|

When designing a horizontal loop this choice has critical variables to consider. In some regions where heating is most important, a consideration is noted when designing a horizontal loop is the depth of the water table between the certain months, what type of soil the loop will be in. These factors will allow us choose the right type of trench and pit loop. |

|

Horizontal Loops |

|

Need Help? Call :

(512) 704-8200 (229) 638-2889

Email: sales@geothermaldesign.net |

|

Need Help? Call :

(512) 704-8200 (229) 638-2889

Email: sales@geothermaldesign.net |